Researchers are working to overcome challenges in order to bring wearable, electric, wound-healing devices to clinical practice.

Published : Jan 07,2022 / DOI : 10.1080/14686996.2021.2015249

Tiny dressings that generate electricity in response to movement could accelerate wound healing and tissue regeneration. Scientists in Taiwan reviewed the latest advances and potential applications of wound healing technology in the journal Science and Technology of Advanced Materials.

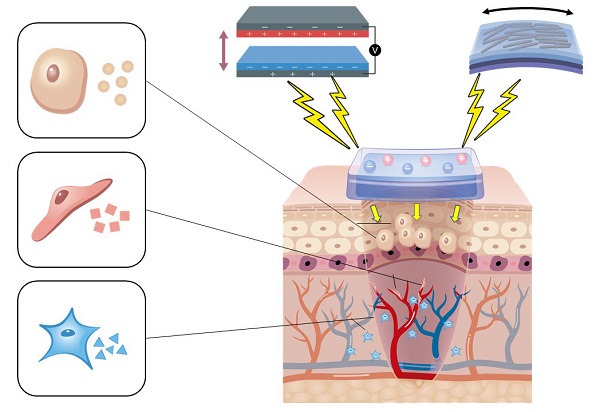

The natural wound healing process involves complex interactions between ions, cells, blood vessels, genes and the immune system; with every player triggered by a sequence of molecular events. An integral part of this process involves the generation of a weak electric field by the damaged epithelium – the layer of cells covering tissue. The electric field forms as a result of an ion gradient in the wound bed, which plays an important role in directing cell migration and promoting blood vessel formation in the area.

Scientists discovered in the mid- to late-1900s that stimulating tissue with an electric field could improve wound healing. Current research in this field is now focused on developing small, wearable, and inexpensive patches that aren’t encumbered by external electrical equipment.

This has led to research on piezoelectric materials, including natural materials like crystals, silk, wood, bone, hair and rubber, and synthetic materials such as quartz analogs, ceramics and polymers. These materials generate an electric current when exposed to mechanical stress. Nanogenerators developed using the synthetic materials are especially promising.

For example, some research teams are exploring the use of self-powered piezoelectric nanogenerators made with zinc oxide nanorods on a polydimethylsiloxane matrix for accelerating wound healing. Zinc oxide has the advantage of being piezoelectric and biocompatible. Other scientists are using scaffolds made from polyurethane and polyvinylidene fluoride (PVDF) due to their high piezoelectricity, chemical stability, ease of manufacturing and biocompatibility. These and other piezoelectric nanogenerators have shown promising results in laboratory and animal studies.

Another type of device, called a triboelectric nanogenerator (TENG), produces an electric current when two interfacing materials come into and out of contact with each other. Scientists have experimented with TENGs that generate electricity from breathing movements, for example, to accelerate wound healing in rats. They have also loaded TENG patches with antibiotics to facilitate wound healing by also treating localized infection.

“Piezoelectric and triboelectric nanogenerators are excellent candidates for self-assisted wound healing due to their light weight, flexibility, elasticity and biocompatibility,” says bioengineer Zong-Hong Lin of the National Tsing Hua University in Taiwan. “But there are still several bottlenecks to their clinical application.”

For example, they still need to be customized so they are fit-for-size, as wound dimensions vary widely. They also need to be firmly attached without being negatively affected or corroded by the fluids that naturally exude from wounds.

“Our future aim is to develop cost-effective and highly efficient wound dressing systems for practical clinical applications,” says Lin.

Further information

Zong-Hong Lin

National Tsing Hua University

Email: linzh@mx.nthu.edu.tw

Research paper: https://www.tandfonline.com/doi/full/10.1080/14686996.2021.2015249

About Science and Technology of Advanced Materials (STAM)

Open access journal STAM publishes outstanding research articles across all aspects of materials science, including functional and structural materials, theoretical analyses, and properties of materials. https://www.tandfonline.com/STAM

Dr. Yoshikazu Shinohara

STAM Publishing Director

Email: SHINOHARA.Yoshikazu@nims.go.jp

Information

- Authors

- Fu-Cheng Kao, Hsin-Hsuan Ho, Ping-Yeh Chiu, Ming-Kai Hsieh, Jen-Chung Liao, Po-Liang Lai, Yu-Fen Huang, Min-Yan Dong, Tsung-Ting Tsai & Zong-Hong Lin

- Citation

- Sci. Technol. Adv. Mater.23(2022)1.

- URL

- http://doi.org/10.1080/14686996.2021.2015249